India has a long history of fine textiles, both cotton and silk. Traditional printing methods have influenced designers all over the world. Here are of some of the techniques used. Tiggy has a passion for Indian textiles, Indian print and printing techniques, so we decided to track down some of the traditional textile printing methods and record them before they vanish.

A traditional method going back hundreds of years - by using string or thread to bind the cloth tightly to resist the dye getting to the cloth. Traditional tribal patterns are created this way.

As each item takes time and patience to prepare and each piece is unique.

Here in Udaipur this family have passed this knowledge down from generation to generation been making individual tie-dye items to a very high standard of workmanship for centuries

Ilyas mixing hot dyes. His ability to match colour exactly is amazing.

More

Block printing by hand

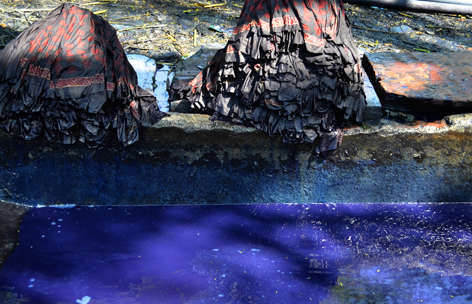

Indigo is a natural plant that grows well in India. As demand is so high these days a synthetic substitute is now used.

With this block printing technique you can either print a pattern on the fabric and over-dye the colour by immersing the whole cloth into the indigo vat.

Or by using a resist 'Dabu' paste (mud) they hand print a pattern that will prevent the dye getting to the cloth. When the resist is washed off the pattern is revealed.

The rust and red colour dye is made from iron soaked in water and jaggery (sugar).

Preparing the the Dabu resist (mud) so it is fine enough for printing.

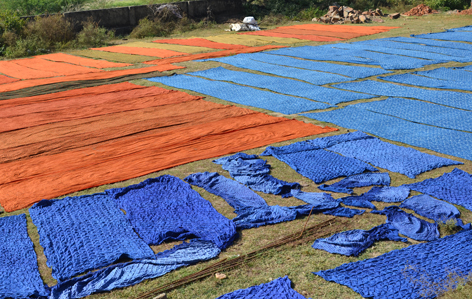

The dyed cloth is laid out in a field to dry in the sun

Block printing and Indigo

Really sophisticated designs can be made by using multiple block prints with more than one colour - and a resist, before immersing the cloth in the indigo vat.

This family has really perfected this method and is high on fashion designers list, and supplying cloth for well known stores.

Traditional tie-dye techniques are now being overtaken by screen printing. They can reproduce and repeat all the traditional designs in a fraction of the time.The cloth is printed outdoors, and dries quickly in the heat.

The above photos were all taken in Rajasthan. To find out more about these locations - or to book Tiggy for talks on India, Indian printing or sewing techniques with demonstration workshops contact

tiggy.rawling@btconnect.com

The prepared cloth - tied and stitched and pulled tight

After first dip the cloth is re-tied and or stitched.

The cloth is re-tied for each colour

A selection of finished items

Blue is not the only colour!

Block printing with dye and a dabu resist.

Dyeing and washing the cloth

Block printing by hand. Setting the pattern on the cloth.

As the popularity for tie-dyed fabric has grown, so has the need to increase production. Here a family-run business are producing tie-dye on a lot larger scale. Using string, rubber inner tubes or even plastic to bind large amounts of cloth, together with larger dye pots means they are able to produce cloth on a much grander scale.

Washing the cloth in preparation for printing

The whole cloth is submerged into the indigo vat

Washing the printed/dyed cloth. The old water is channelled into the fields to water the crops

The dyed cloth drying in the sun

Some of the finished items

The washed white cloth is sorted

After the first dip the cloth is boiled to set the dye.

Now wrapped to resist the second dyeing.

Finished cloth drying in the sun on the roof tops.

Plain cloth drying in the sun.

The whole family is involved.

Screen printed cloth is produced on a large scale. Fully printed cloth just tumbles off the press and is shipped out by the lorry-load each day.

Block printing and Indigo

Aavaran produce exclusive indigo designs and cloth which they make into fashion garments and sold in their own shop in Udaipur.

Block printing by hand. Setting the pattern on the cloth.

Sorting and finishing the cloth

Preparing the the Dabu resist

Tiggy with Alka Sharma

A rack of garment patterns

A finished traditional pattern

Small dot patterns require every 'dot' to be tied by hand